The Institute of Process Imaging at TUHH is home to a worldwide unique large-bore vertical MRI scanner, that was specifically designed for the study of process engineering systems. The device allows unprecedented tomographic insights into large multiphase flow systems, quantifying the spatial distribution of phases, flow, temperature, and diffusion parameters among others. The hardware was designed and built by the institute in cooperation with Tesla Engineering Ltd and Philips Healthcare. The system was co-funded by the DFG under the Major Research Instrumentation program under project number 422037415 and the city of Hamburg.

We are open to collaborations with industrial partners in joint research projects. Please contact Alexander Penn for further information.

MRI System Specifications

The picture on the left shows the magnet of the MRI system before construction of the wooden platform around the magnet. The magnet center is located 4 m above the floor level to allow tall reactors to be inserted from below. The system features one of the world’s largest bore diameters in a vertical MRI magnet, allowing to fit columnar samples (fluidized beds, bubble columns, contactors, pipes, rotating packed beds, stirred tank reactors, etc.) of up to 400 mm in diameter and several meters in height.

| Magnetic field strength | 3 Tesla |

| Max. spatial resolution | 0.4 mm isotropic |

| Max. temporal resolution | 7 ms |

| Max. reactor diameter | 400 mm |

| Max. reactor height | 3000 mm |

| Max. reactor weight | 500 kg |

Superconducting magnet

The conduction-cooled superconducting magnet of this MRI system is worldwide unique for its large size and vertical orientation. It was especially designed to accommodate tall columnar samples and reactors, common in process and chemical engineering. Samples are lifted into the bore of the magnet for examination from below. Passive shims are visible on the inner facing surface of the magnet. They are precisely placed in specific locations to maximize magnetic field homogeneity.

Gradient coil

The gradient coil of the MRI system is shown on the left while it was installed into the magnet. It produces strong and rapidly switching magnetic field gradients, enabling MRI imaging at high spatial resolution and the quantification of flow and diffusion phenomena.

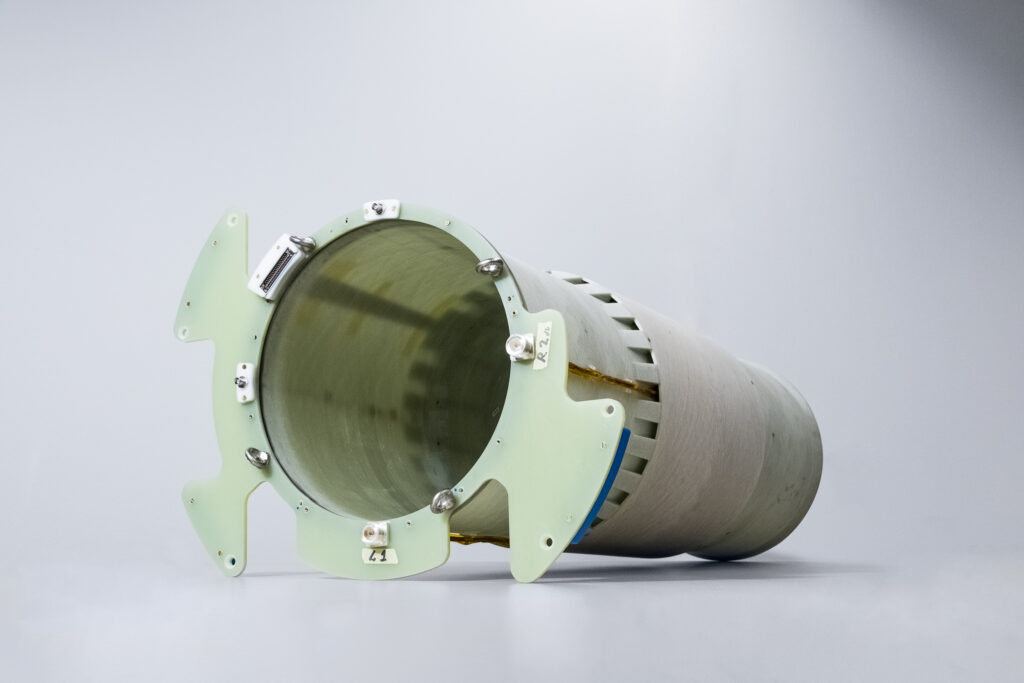

Radiofrequency coil

The radiofrequency bore coil shown on the right is used to excite the nuclear spins of the sample and detect the MRI signal. It features a birdcage design for high B1 homogeneity and is rated for a total peak power of 27 kW that leads to a high signal-to-noise ratio in the MR images.