Magnetic resonance imaging in chemical and bioprocess engineering

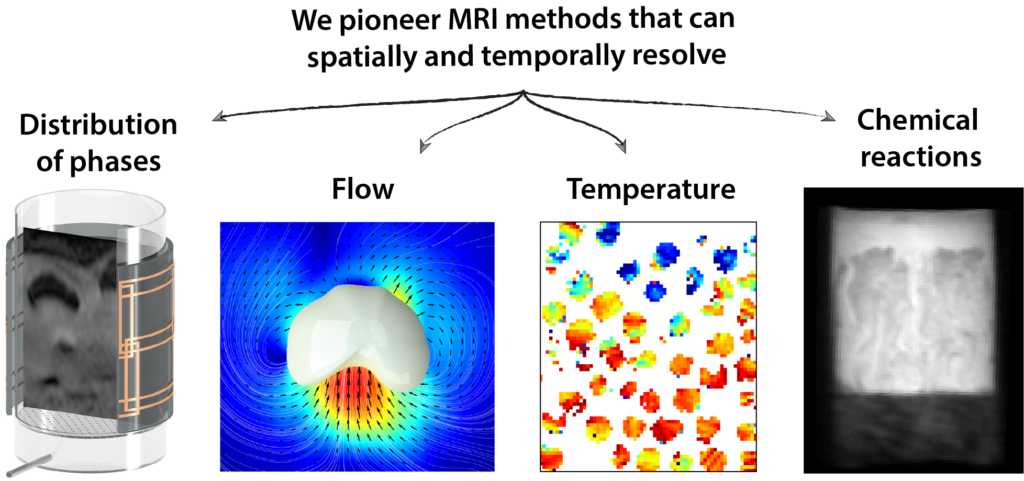

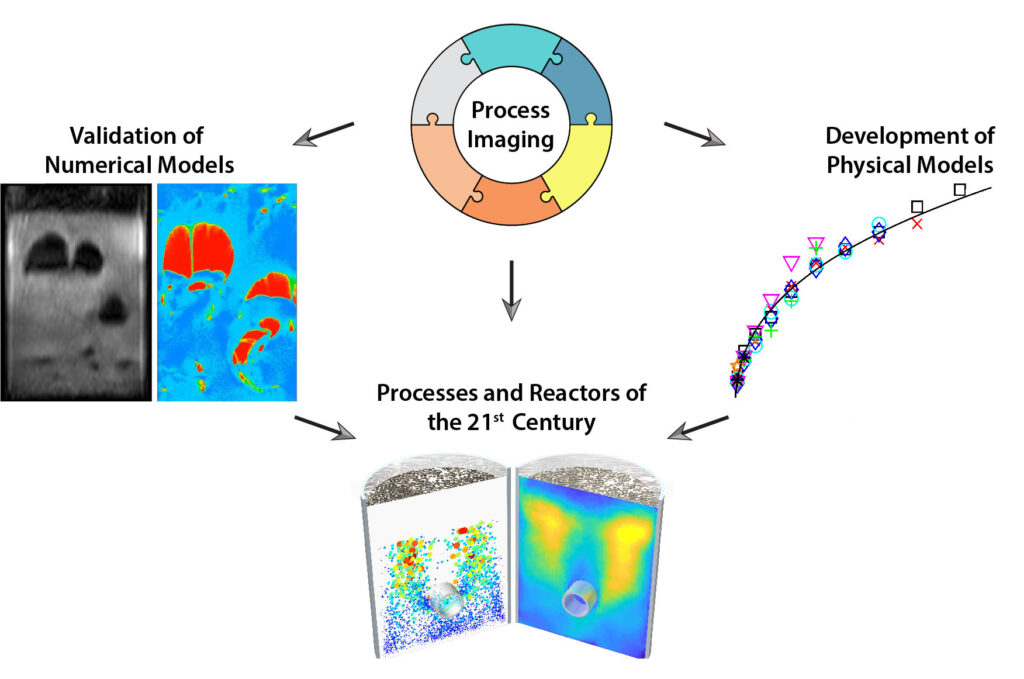

Material transport, temperature distributions and chemical composition are important process conditions that need to be controlled within chemical and biochemical reactor systems. At Hamburg University of Technology, we develop process imaging techniques based on magnetic resonance that can quantify the local phase distribution, flow, temperature, and chemical composition of multiphase gas-solid and gas-liquid and gas-liquid-solid reactor systems.

We use our techniques to study characterize reactor types including fluidized and spouted beds, bubble column reactors, and pipe reactors. Since early 2023, the institute is home to the world’s largest vertical MRI system for process engineering applications, that allows to investigate reactors of up to 40 cm in diameter and several meters of height. The systems have to be non-magnetic and ideally non-conductive. Materials as well as reactors can be investigated.

Furthermore, the IPI is developing and applying magnetic resonance methods to enable access to these critical parameters. A major challenge is the spatial and especially temporal resolution as well as access to complex process parameters. These efforts include:

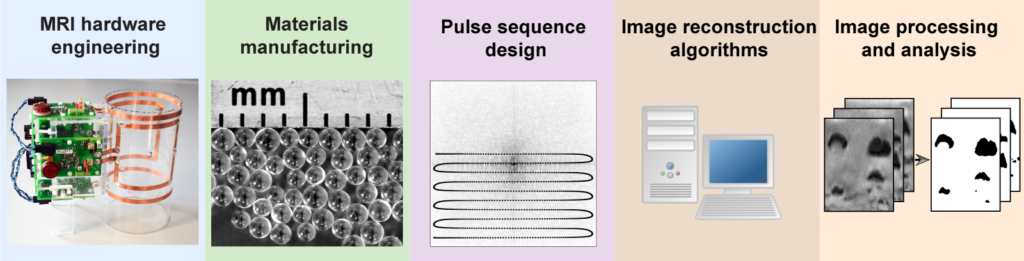

- Manufacturing of modern MRI hardware, such as detector arrays or microcoils, leading to significant improvements in image quality.

- Pulse sequence design aimed at speed and reliability, which can increase temporal resolution to levels needed for highly dynamic processes.

- Synthesis of MRI contrast agents, also for granular media, for increased image quality.

- Development of powerful image reconstruction algorithms and

- Automated image processing and analysis breaking down information to process relevant parameters, employing among others computer vision and machine learning approaches.

The IPI collaborates with many institutes within the TUHH, but also with researchers at ETH Zürich, Columbia University and Osaka University.